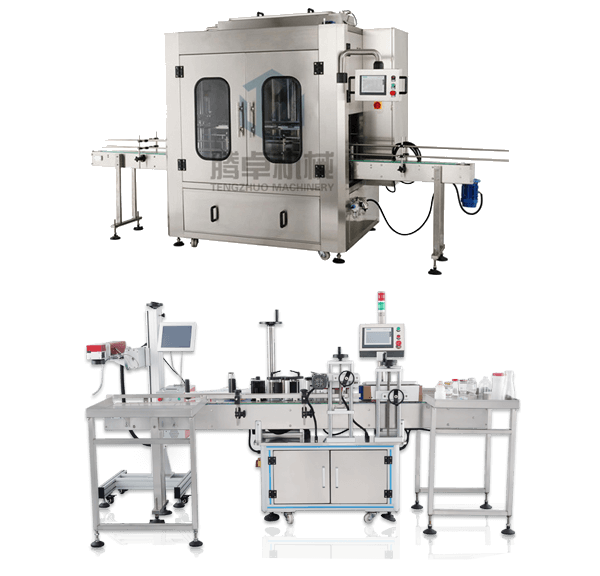

In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

Select nine of the advantages of liquid filling machine

Servo liquid filling machine is suitable for quantitative filling of liquid or cream materials such as food, wine, beverage, daily chemicals, grease, pesticides, veterinary drugs, condiments, sauces, etc.

Nine advantages of using servo liquid filler:

1. This servo liquid filling machine integrates machine, electricity, light and instrument. It is controlled by single chip computer. It has the functions of automatic quantification, automatic filling and automatic adjustment of measurement error.

2. Fast speed: Using servo control and light control technology, the fastest speed can reach 150 bottles/min.

3. High accuracy: filling accuracy can be controlled within 1%.

4. The filling range is wide: the same quantitative filling machine has arbitrary capacity within 5-5000ml and high compatibility.

5. Fast disassembly, cleaning and convenient maintenance by clamp connection

6. Counting function

7. Configuration of filling head to effectively prevent dripping and wire drawing

8. Automatic fault inquiry and alarm function of material over liquid level

9. Stainless steel is used to make contact parts with materials, which is easy to clean and prevent cross-contamination.

Recommend

-

Soft package liquid filling sealing detection

-

High quality filling equipment to ensure food safety

-

Knowledge of liquid filling machine

-

Liquid filling machine system process requirement

-

How to improve the start-up speed of liquid filling machine

-

Select nine of the advantages of liquid filling machine