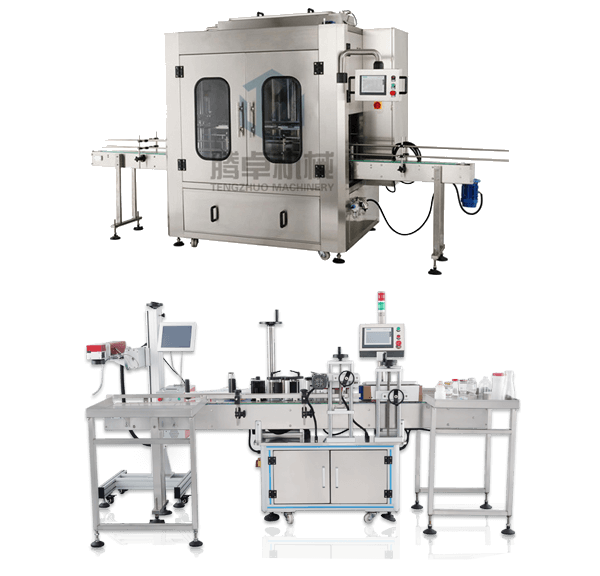

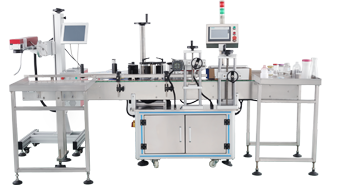

In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

Knowledge of liquid filling machine

For the process:

First of all should be based on the nature of the filling material (viscosity, foamability, volatile, meantime, etc.) to choose the suitable filling machine, in order to meet the process requirements. For example, fragrance is thick liquid, volatile aromatic substances in order to avoid losses, should be generally adopted should the cup type or normal pressure filling machine; For juice class material liquid, in order to reduce the contact with air, to ensure product quality, the general should use vacuum plus juice filling machine. Secondly, should keep filling machine production capacity and process before and after processing and packaging machinery production capacity to match.

High productivity and product quality:

Productivity directly reflect the production capacity of production line, so the higher productivity, the economic efficiency, the better. In order to improve the quality of products, should choose equipment of high precision, also has a high degree of automation of filling machine. But the equipment price increase, increase the unit cost of the product. So when choosing filling machine, should be combined with production process requirements, comprehensive consideration of relevant factors.

Wide range of process:

Is the scope of filling machine process refers to its ability to adapt to different production requirements. Process range is wide, more can improve the utilization rate of equipment, realize multi-usage, it is using the same equipment filling can be a variety of materials and a variety of specifications. So in order to adapt to drinks, beverage industry, many varieties, many specifications of the production requirements, should choose the filling machine process range as wide as possible.

Recommend

-

Soft package liquid filling sealing detection

-

High quality filling equipment to ensure food safety

-

Knowledge of liquid filling machine

-

Liquid filling machine system process requirement

-

How to improve the start-up speed of liquid filling machine

-

Select nine of the advantages of liquid filling machine