In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

3 in 1 filling machine working principle and application instance

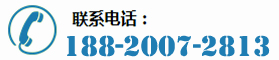

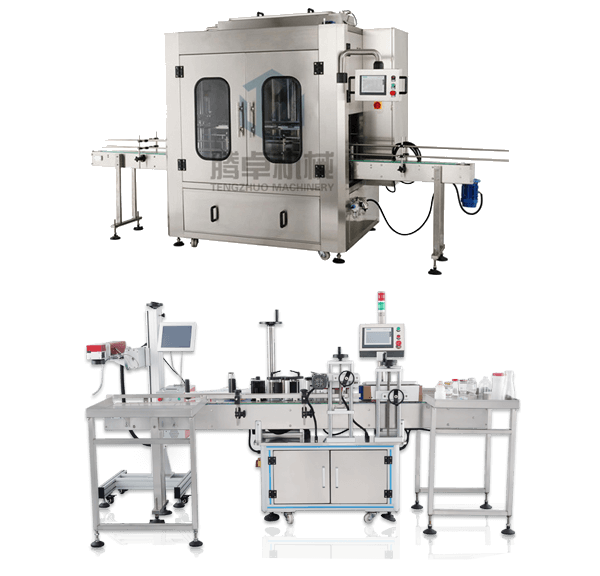

Overview of 3-in-1 filling machine

3-in-1 filling machine, using stainless steel fuselage, filling, lower cover, screw cover are completed at one time. Mainly applicable to food, beverage, daily filling cap, can also be used for other special-shaped filling cap, automatic filling, automatic lower cap, automatic screw cap sealing; the use of imported stepless speed change system, adjustable production speed; the use of cam indexer, so that the lower cap positioning accuracy, machine running smoothly; imported food-grade stainless steel, to ensure that products meet GMP standards.

Working Principle of 3-in-1 Filling Machine

Inspect the sealing surfaces with air source, adjust the air pressure from 0.3 MPa to 0.4 MPa to adjust the oil intake, and spray a drop of oil after several times of general action, and check the fuel injection regularly. Anti-drip and leak filling system: When filling, the cylinder moves up and down to drive the stuffy head. When the cylinder moves upward, the stuffy head moves upward, that is, the valve opens and fills the material. When the cleaning is finished, the control valve is closed, the motor stops turning, the system restores to its initial state, and the next process begins.

Application of Three-in-One Filling Machine

This machine is mainly used for daily filling operations. The machine integrates filling, managing, lower cover and rotary cover into one body, realizing automation in the whole process. It is suitable for filling and heating temperature control devices of cosmetics, cream products, water agents, etc. It can also be used for hot filling. The adjustment of the trial bottle type of each part is realized by turning the handle, which is easy, convenient and fast. The filling method adopts a new type of micro-pressure filling, which makes the filling speed faster and more stable. Therefore, compared with the machine of the same specification, this machine has higher output and greater benefit. The machine uses advanced programmable controller to control the automatic operation of the machine, photoelectric detection of the operation status of various components, so it is highly automated and easy to operate. On this basis, the machine can change the filling equipment to form a low vacuum filling mode.