In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

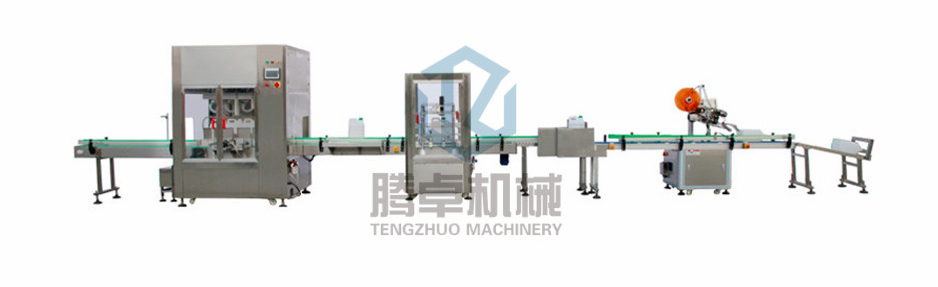

Urea liquid production line for vehicle

Overview of equipment:

Vehicle urea filling production line is a kind of automatic quantitative packaging machine, mainly used in food, chemical and other industries. Advanced automatic control system of optics, electricity and gas is adopted to realize automatic production of barrel feeding, positioning, filling and discharging.

Technical parameters:

Completion of the action: manual bottle – Automatic Weighing Filling – Manual plug capping (optional automatic capping) – automatic capping – automatic pushing down products – automatic labeling – Manual bottle closing

1, product categories: barreled

2. Filling materials: liquid

3. Output: customized according to requirements

4. Material contact parts are 316L material, filling machine and capping machine conveyor belt side plate and rack are 304 material, exposed part is brushed varnish protection, prevent material contact after corrosion; pipeline with quick connection, easy to clean and replace;

5. the human-machine interface program has cleaning function, and all programs can switch between two Chinese and English languages.

6.the material can be disassembled for sanitation; the following pipes have butterfly valves; the pot is 2mm thick.

7. Raw material hose is silicone tube.

(above is standard type technical parameters, other special requirements and functions, can be customized!)

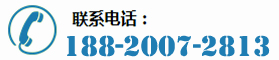

Filling machine

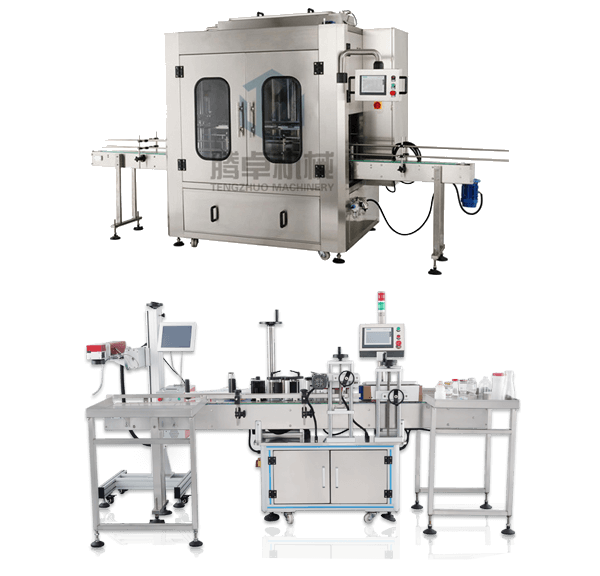

Filling machine Labeling machine

Labeling machine Screw cap machine

Screw cap machine Casing shrink..

Casing shrink.. Bottle washing..

Bottle washing.. Automatic medicin.

Automatic medicin. Automatic filling ..

Automatic filling ..  Automatic filling ..

Automatic filling ..