In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

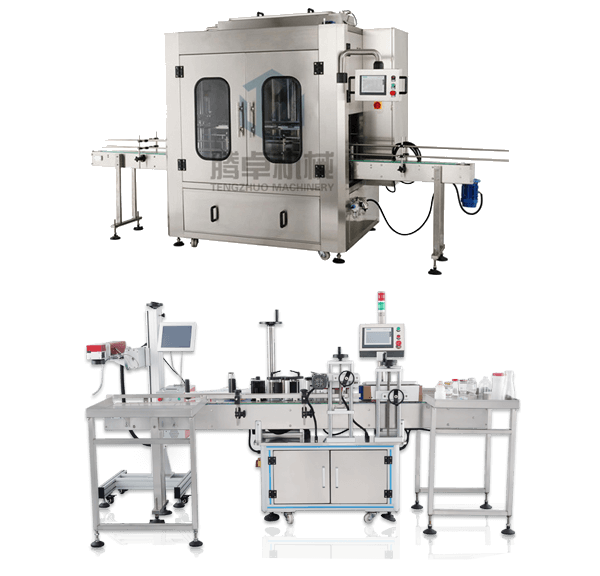

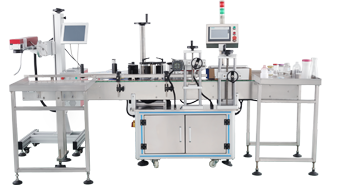

Bilateral labelling machine

| Introduction of equipment |

This series of labeling machine is suitable for labeling flat bottles with high precision on one side and two sides. It can be used for labeling cylinders or even square. Four-sided or three-bread enclosure labeling of bottles, special-shaped bottles and square bottles greatly enhances the scope of use of the equipment, and is thorough for economic users and efficiency-seeking users. It solved the big problem of one machine with multiple functions. |

| Equipment features | |

| header |

1. Multidimensional space adjustment: the header can realize 8-dimensional space adjustment, inclination adjustment, additional position display, accurate positioning adjustment. 2, the horizontal translation of the header: in the header work, the fine-tuning of the labeling position can be achieved through the horizontal translation header. 3, all regulatory agencies can achieve rapid regulation without tools. 4. Double pressure roller design is used to improve the tension of labels, especially for ultra-thin labels. 5. All the structural parts are processed by numerical control, and each part is cooperated with high precision to ensure the precision level of the equipment. 6. The new type of label clutch makes the tension more stable and runs more smoothly.More stable. 7. Special scraper bracket for easy adjustment. |

| Pressure belt mechanism |

1, main motor double row chain drive, increase the transmission torque, reduce the deformation of the chain. 2. Separate belt-pressing gasket is conducive to heat dissipation, and different pressure settings can be adopted according to the requirements of different workstations. 3, press the belt long span support, the twin screw adjustment, the chain between the screw drives, realizes the synchronous adjustment. 4, large range height adjustment, adjustable area 0~400mm, easy to replace product categories. |

| Reshaping mechanism |

1. Adopting mechanical transmission, the main conveyor line, pressing belt and shaping belt are driven by gears and driven by a high-power servo motor, which runs completely synchronously.And it can realize speed control without segment. 2, increase the spiral bevel gear transmission to improve the safety performance of the operation. 3, two dimensional space adjustment, increase the scope of application of equipment. |

| Conveyer line |

1. Adopt high precision conveyor belt to achieve absolute synchronization between conveyor belt and pressure belt. 2, widened strip design, high power servo motor drive, expanded the scope of use of the device. Changing the running inertia of the conveyor line to get more accurate labeling results. |

| technical parameter |

|

||

| Applicable product range |

Square bottle: thickness 20~90 (mm) length 50~200 height 100~250 Round bottle: diameter 35~90 |

pressure | 0.5-0.8Mpa |

| Applicable label range | High 20~80 (mm) long 20~200 (mm) | Rated voltage | 220V/50Hz |

| Throughput | Square bottle: 50-120 bottles / minute bottle: 15-30 bottles / min. | Power | 2200W |

| Pastes the sign precision |

Square bottle + 1 mm (plane, left and right direction) Round bottle + 1 mm (height direction) (excluding bottle and label error) |

Filling machine

Filling machine Labeling machine

Labeling machine Screw cap machine

Screw cap machine Casing shrink..

Casing shrink.. Bottle washing..

Bottle washing.. Automatic medicin.

Automatic medicin. Automatic filling ..

Automatic filling ..  Automatic filling ..

Automatic filling ..